The extremely high output of boron nitrate heaters, also referred to as High Flux Heaters, Ultra Heaters, or Very High-Performance Heaters, is achieved by using boron nitrate technology which ensures that the nickel-chrome 80/20 spiral unrolls its health within the heater. This is the so-called Joule effect.

Depending on the conditions of use (convection, conduction or radiation) and the surface temperature of the elements, the watt density of these heaters can go even over 150W/cm2.

Technical advice? Ask for more information

Technical adviceThe team of specialists of Heating Group International is happy to give you advice for your specific situation and if boron nitrate heaters can be a good option for your process too.

In the past years, our company Heating Group International has delivered multiple projects with boron nitrate heaters for applications with high circulation speed, high pressure (200bar) and temperatures up to 1100°C in projects for turbines, power plants, reactor and for forges.

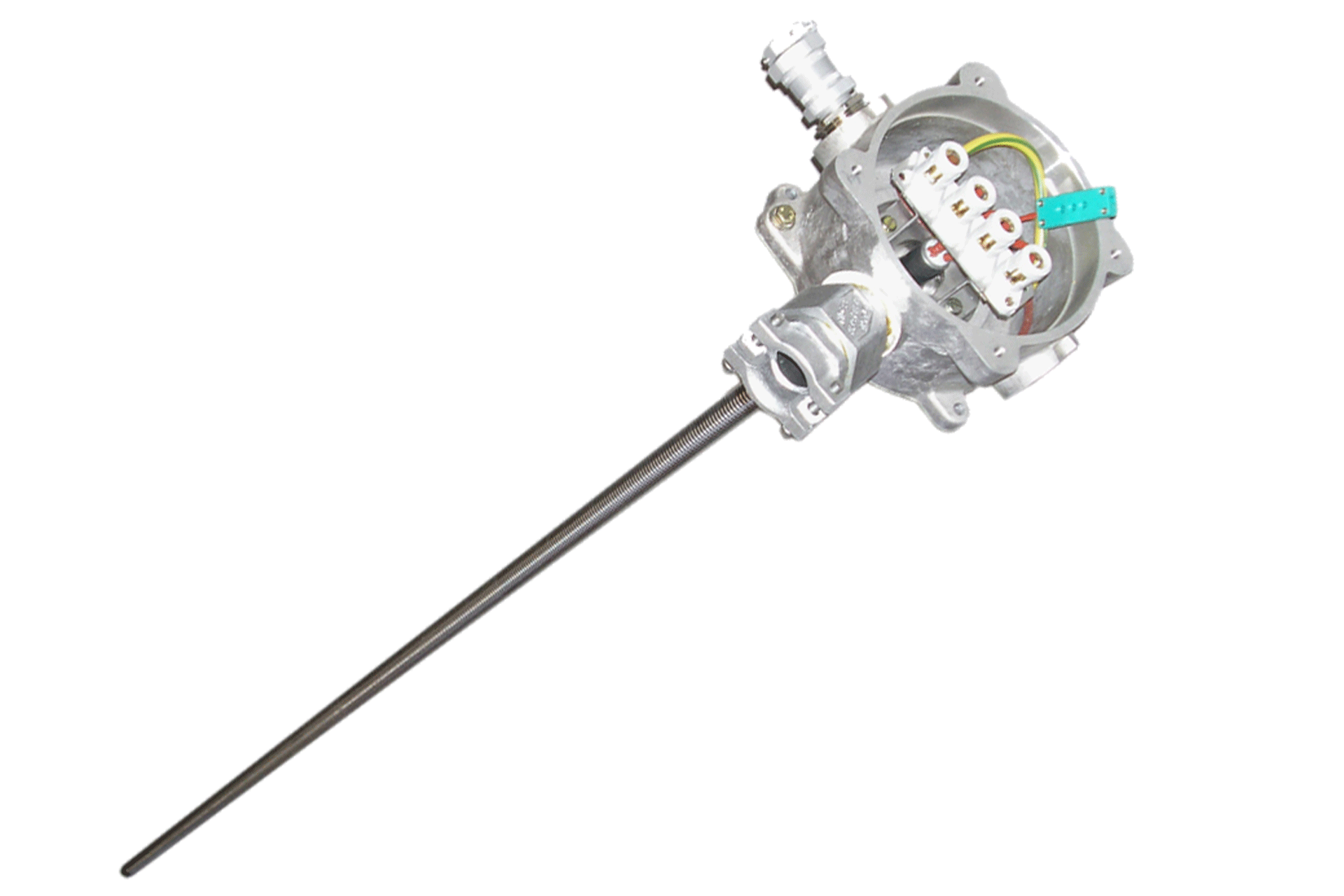

Another typical use of boron nitrate heaters is the use as bolt heaters. In this case, the boron nitrate heaters are used as cartridge heater to heat up bolts and nuts, or as straight tubular elements at forced convection within electric heaters.

Traditionally hollow bolts were heated up by inserting a heating element isolated with magnesium oxide. Our promise to you: the use of Heating Group International bolt heating with boron nitrate technology reduces the assembly time (tightening of the screw connections) and dismantling time (loosening the screws) significantly.

Heating Group International B.V. © 2024

Do you have questions or do you need advice? On our customer service page you can find frequently asked questions and on the contactpage we have provided all information required to contact us.