The Dutch government has set energy transition goals to ensure a more sustainable and future-proof Dutch industry. The goal is to achieve a 40% to 50% emission reduction of CO2 by 2030 compared to 1990. In this article we explain the basics about electrification and the ways companies can benefit from it. In the following articles we further discuss some sub-topics.

An important means to achieve the goal as set above, is electrification. By switching from (fossil) energy sources to electricity, the industry becomes more sustainable because of the decrease in CO2 emission. By taking a critical look at parameters such as insulation, consumption and control, and if all this is supported by solar panels, for example, your company not only meets the sustainability standards but can also generates significant savings.

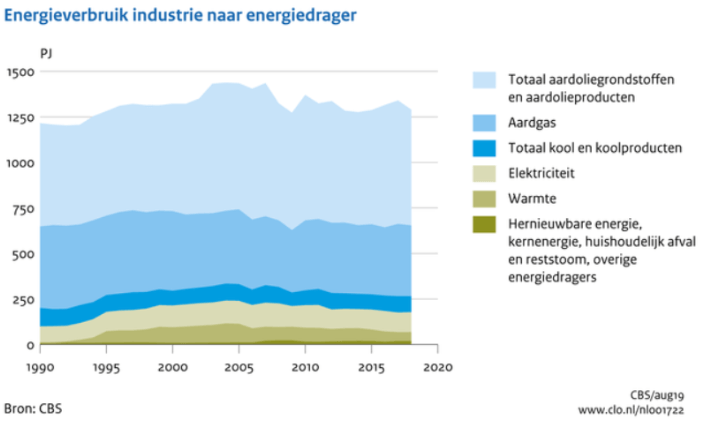

The image below illustrates the amount of petroleum materials and products and the amount of natural gas that is still being used in the industry in the Netherlands. In addition to the goals of making the industry more sustainable, there are other factors that almost force us to switch to alternatives. With current consumption, the accessible sources of natural gas will be used up within the next 60 years. For petroleum, this will even be so already in 40 years. In addition, we are highly depending on oilproducing countries for the use of petroleum, as we only produce 8% ourselves. Due to all these factors, the switch to electricity is a necessity. In the coming years some substantial shifts will take place in the graph below!

Many companies are postponing the switch to another energy source. They are afraid that it will entail high costs, that the switch will take a long time, that production processes will come to a stop and that the possibilities are limited. There is also still the misconception that electric heating is very expensive. Usually the costs turn out to be lower than expected. By using (partial) wind or solar energy when converting to electricity, costs can be significantly reduced. In addition, electric heating is virtually maintenance free in contrary to a lot of other energy sources. This reduces the yearly maintenance costs significantly and therefore also the production downtime. Electric heating is usually easy and quick to install. In most of the cases the processes can be converted to electricity by using standard applications, but in fact the possibilities are endless. From high temperatures and capacities to very precise control of the processes, all is possible.

Do you have any questions regarding this article, or would you like information about electrification within your industry? Feel free to send us an email at tgi@heatinggroup.eu

In our next article, we'll cover Power-to-Heat.

Heating Group International B.V. © 2024

Do you have questions or do you need advice? On our customer service page you can find frequently asked questions and on the contactpage we have provided all information required to contact us.