In 2020, the Netherlands placed the most wind turbines of all European countries, which was good for a 1979 Megawatt power. Up to 2030, 10 offshore wind turbine parks will be added. In all these windmills, heating is required in various places to ensure optimum operation.

To ensure proper overhaul and maintenance, we can provide a special system that keeps the rotor blades warm during the maintenance period. The PHBC-6 system consists of a portable controller (tablet-style) combined with heating jackets with built-in temperature sensors.

The controller also measures and records ambient temperature and humidity. This system offers several advantages:

The production and delivery of these heating blankets are bespoke because each application is different and the material of the rotor blades plays a role. Our consultants calculate the power density needed to achieve a perfect TG value every time. Due to the light material and flexibility, the heat blankets are easy to use.

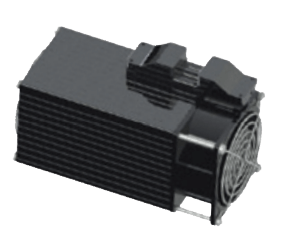

In wind turbines, fan heaters are used in different locations. Due to the rough conditions that can arise from the weather and the high altitude, these fan heaters must meet various requirements.

Especially for wind turbines, Heating Group International provides fan heaters that operate at temperatures down to -40ºC and are also suitable for high altitude applications. We supply these fan heaters in various versions with different voltages and wattages. This depends entirely on the application. The heaters are CE or UL/CSA certified.

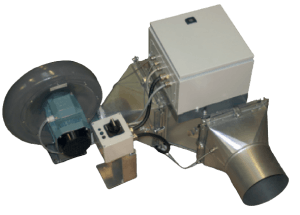

With the specially developed units for frost protection and de-icing, freezing of rotor blades is prevented in cold climates. This prevents downtime. Whether the wind turbine is switched on or off, this unit can be used continuously if desired.

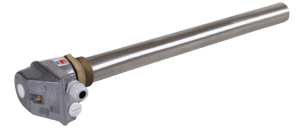

Both in the gearbox and the hydraulic unit, immersion elements are used for heating and maintenance of oil and lubrication systems. Heating Group provides immersion elements that meet all requirements and specifications for use in wind turbines. There are different voltages, wattages and lengths possible and there is a choice between flange or wire. A big advantage of these immersion elements is that they are very quick to install and that the oil does not need to be drained.

The built-in pump of these flow heaters circulates the lube oil through the gearbox. The flow heater is equipped with a pump, temperature limiter, and Pt100 sensor. In addition, we can also supply glycol heaters for pre-heating cooling water in the cooling/heating system in inverters of wind turbines before start-up.

Temperature differences create condensation even in sealed enclosures. In combination with dust and aggressive gases, condensation causes corrosion, resulting in stray current and arcing. In addition, too high or too low temperatures can cause parts to fail. This provides a high-security risk and causes huge costs due to downtime. Heating Group provides cabinet heating that prevents condensation. This ensures optimum protection of the control panel.

The lightweight, thin silicone heating mats have a low thermal mass and fast warm-up time. Silicone mats have even more advantages:

Silicone heating mats are used for heating battery trays, pipelines and lighting systems.

Our consultants will be happy to provide you with detailed advice on the different applications of electric heating in and on wind turbines and rotor blades. Heating Group has many years of experience in the production and worldwide supply of electric heating and many of our heating systems are produced by ourselves in the production hall in Wijchen.

Please feel free to contact us if you have any questions or if you would like to schedule a free consultation, we will be happy to help you.

Heating Group International B.V. © 2024

Do you have questions or do you need advice? On our customer service page you can find frequently asked questions and on the contactpage we have provided all information required to contact us.