Cast heaters are a safe and efficient integrated solution for heating a gas process or for heating corrosive liquids and suitable for high process pressures. There are multiple benefits when using cast heaters over traditional heaters. For example, the indirect heating and precise temperature control.

Technical adviceHGI cast heaters are a safe and efficient integrated solution for heating a gas process (O2, Ar, N2). Corrosive liquids can also be heated, especially when higher temperatures of the heating elements are not preferred. The cast heater was primarily developed as a seal gas heater which has a high operating pressure combined with a low flow rate.

Heating O2, Ar, N2, CO and CO2 gasses and corrosive liquids, compressed air, steam, superheated water, balm

Seal gas heating

Defrosting of ambient air evaporator

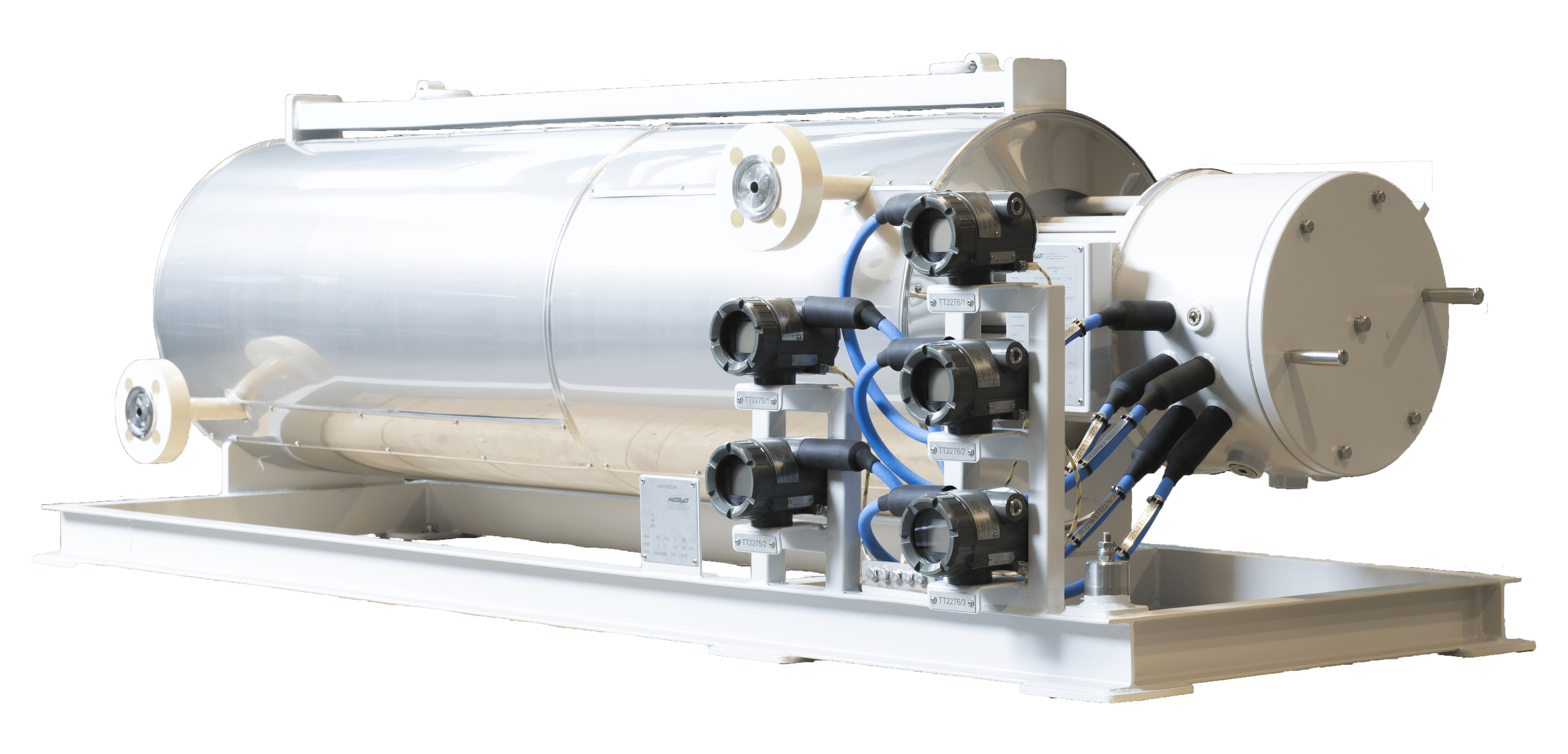

The moulded construction offers great advantages over traditional heaters. Heating gasses using cast heaters prevents overheating of the electrical heating elements. The spiral coil and the heating elements are cast in an aluminium block, which serves as a heat transfer medium between the heating elements and the spiral transport tube (coil). The liquid to be heated never comes into contact with the heating elements. This flows through the transport tube and is heated to a controlled set point. The aluminium mass retains heat accurately and consistently, ensuring optimal control of the temperature level. This efficient heat conduction also extends the life of the embedded heating elements. To prevent heat loss, the aluminium block is thermally insulated and contained in a metal protective casing.

We design the coil according to ASME VIII div.1 pressure up to 500 bar and a maximum aluminium block temperature of +/- 350 degrees C.

The cast heater is positioned vertically on a footprint, cast heater diameter maximum 500 mm and height approx. 2200 mm.

Use up to approx. 200 kW at 3 x 380V, 3 x 400V and 3 x 690V other voltages on request. Min. working pressure: 2 bar (g).

HGI cast heaters are designed for O2 according to AFGC N ° 174-08 and EIGA Doc13 / 12 / E.

The heater is equipped with sensors with which both the temperature of the aluminium housing (TE411) and the process temperature of the inlet (TE401) and outlet (TE402) can be controlled. These sensors can of course be individually removed and replaced without draining the system. The whole is protected against overheating.

Heating Group has its own panel building department. Our specialists’ design and produce custom control panels for every desired heater. The HGI control panels for cast heaters guarantee stable and accurate process temperature control at a constant or fluctuating medium flow during heating.

Heating Group International B.V. © 2024

Do you have questions or do you need advice? On our customer service page you can find frequently asked questions and on the contactpage we have provided all information required to contact us.