Before and during World War II, Mr. Leen van Stek Sr. worked at Piet Smit shipyard in Rotterdam. In 1945 he started his own business by founding Fa. L. Van Stek.

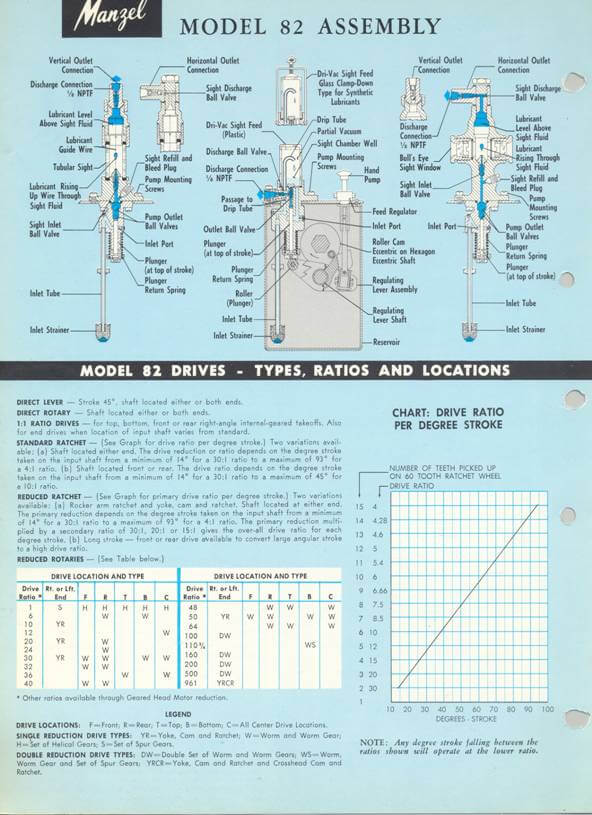

The first supplier for the newly founded company was Manzel from Buffalo (NY) in the US, a manufacturer of lubrication systems. The first delivery took place in 1946. European competition lacked, as a result of World War ll. Because of this, in the following years many lubrication systems were supplied to Dutch industry and equipment manufacturers. The Manzel production line is now part of Graco, a company that Van Stek still works with for smaller projects.

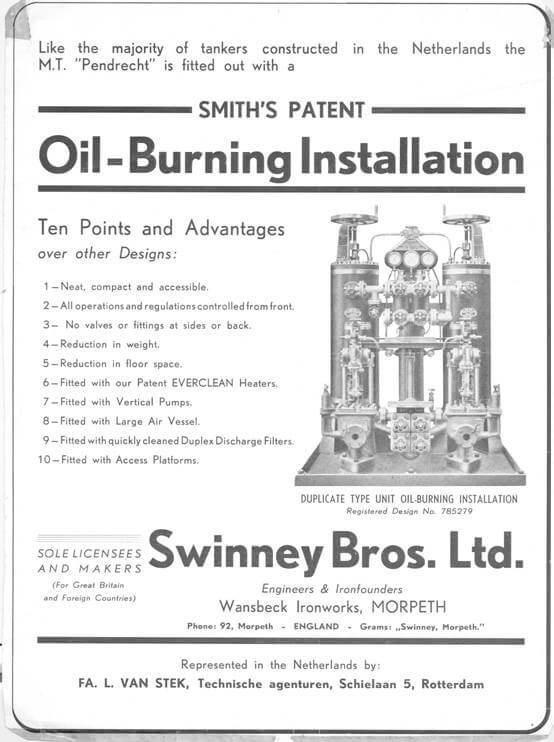

In the 1950s, Van Stek supplied combustion plants to virtually the entire Dutch trading fleet. These were manufactured by Swinney in Morpeth (UK). Also Shell's tanker fleet, which was constructed right after World War ll, was supplied with these burner installations.

Leen van Stek Jr. took over from his father in the 70s and started to enter another market in order to be not depending solely on shipbuilding.

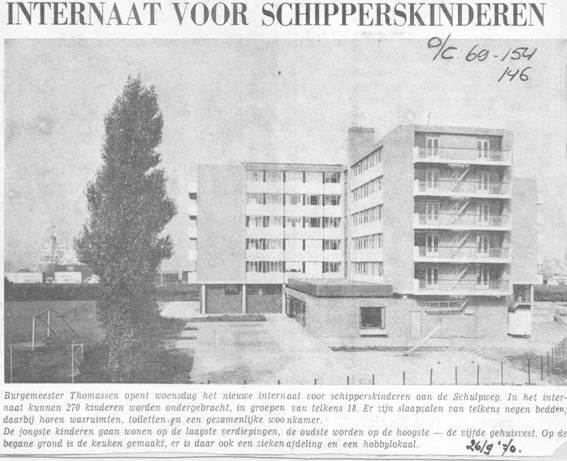

By also developing non-residential construction, the company became less susceptible to economic fluctuations. For example, Van Stek supplied electric storage and circulation boilers for a large number of apartment buildings, including the so-called ERA flats that arose in those years, but also the Rotterdam skipper boarding house and a well-known hotel on the Dam in Amsterdam were provided with Van Stek's installations.

In the same period, first contacts were made with the company Eltron from England, following an application from a large oil company.

Eltron is able to meet the requirements of the oil company and, with input from Van Stek and based on customer demand, the first electrical process heaters for application in an ATEX zone are developed and supplied.

From that moment on, Van Stek has almost become the go-to supplier for most Dutch and also quite a few foreign refineries.

In the 90s the third generation joins the company. The emphasis is increasingly shifting to large industrial projects. For example a series of ovens complete with control systems for both temperature and the added gases for DAF in Eindhoven.

The heating systems are also growing with increasing emphasis on safety and quality, including increasing European regulations such as CE, ATEX and PED. Van Stek's products where among the first on the market that could meet these requirements.

In the 90s the lubrication systems, which are almost the only ones on the market that comply with both ATEX and API guidelines, are again an increasing part of the turnover.

These systems are built entirely according to client specification, with alarm functions, direct or indirect drive and of course electric heating.

After first having been established in Rotterdam and Hellevoetsluis, the company was established in Elspeet since 2003 where there was not only an office but also a 200 m2 (heated) storage and workshop on private property.

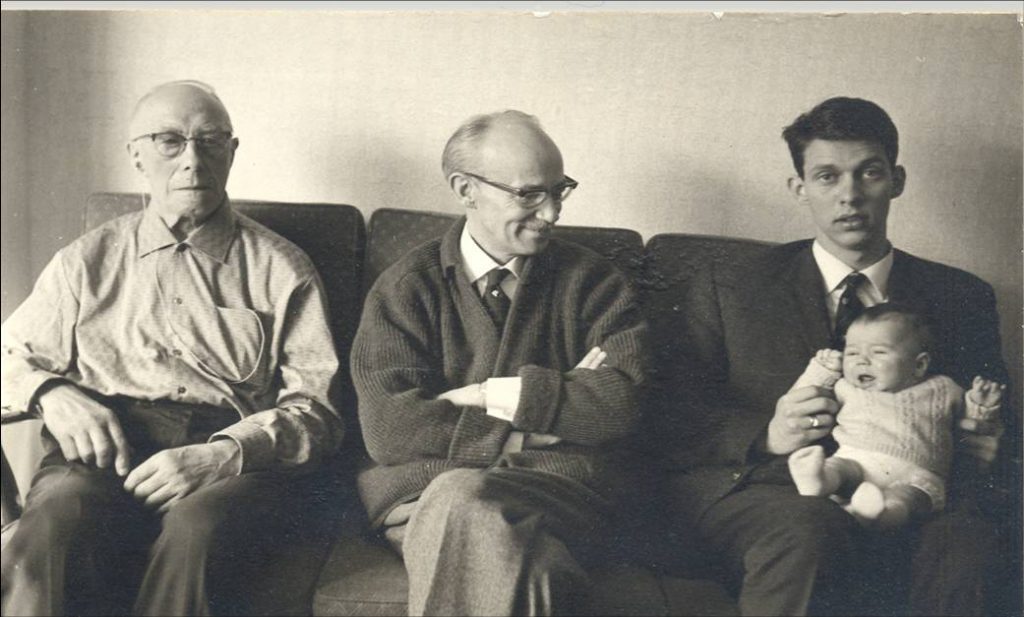

Second from the left the late L. van Stek Sr., founder of Fa. L. Van Stek, to his left his father, to his right his successor the late L. van Stek Jr. with on his lap the third generation and last owner before the transfer to Heating Group International bv, Mr. Jan Hein (photo taken in 1963).

The merger of van Stek with Heating Group International has multiple advantages. J.H. van Stek knows the history of the company and also has vast knowledge about the products. That speeds up the engineering process at Heating Group International. Moreover, we believe that sales are also possible for the lubrication systems within the current customer base of Heating Group International.

Another advantage is that the customers of Van Stek can be better served through the broader product range that Heating Group International offers, with new products like silicone mats, finned tube heaters and heat tracing.

Heating Group International B.V. © 2024

Do you have questions or do you need advice? On our customer service page you can find frequently asked questions and on the contactpage we have provided all information required to contact us.